Legacy Products

JP3 is committed to the continuous support of legacy products for as long as replacement parts and upgrades are available. Please contact us for any questions or support needs.

Verax™ CTX®/CTXe

Introducing Verax™ CTX/CTXe: the ultimate solution for real-time analysis. Swift and accurate, it measures stream compositions, BTU and API gravity across various hydrocarbon streams. With no need for sampling systems or analyzer shelters, Verax™ CTX/CTXe is designed to ensure zero emissions and zero lost product. Versatile and field-deployable, it utilizes advanced technology like NIR laser absorption spectroscopy and custom flow cell designs to prevent fouling, offering seamless integration and control with wireless communication and diagnostic features.

Real-Time Analysis

- Produces stream composition (C1-C9+) and BTU (natural gas) or API gravity (liquids and crude) and more

- 10 second measurement cycle time

- Enables real-time monitoring and control

- Natural gas, NGL, condensate, crude oil and refined fuels capability

- No sampling system (zero emissions and zero lost product from measurements)

- Requires no analyzer shelter

In-Line And Field Deployable

- Flow cell set in-line, at process pressure and temperature

- Utilizes NIR laser absorption spectroscopy and proprietary chemometric models

- No consumables, waste product or calibration gas

- Multi-flow cell option for multiple stream measurement

- Custom flow cell design prevents fouling for maintenance-free use

- Wireless communications & diagnostic capability

Opportunities For Real-Time Analysis

- Gas plant fractionation

- Fuel gas monitoring

- Fractional distillation cuts

- On-line crude tower control

- Refinery blending

- Truck/tank/rail on-load and off-load control

- Real-time NGL product blending

- Stabilizer optimization

- Real-time vapor pressure control for liquids and crude

Verax VPA™

Verax VPA™ is the first optical, online, real-time, vapor pressure analyzer for crude, condensate and NGL streams available to the Oil & Gas industry.

Real-Time Analysis

- Produces RVP, TVP and VPCRx measurements on 30 second cycle

- Zero emissions or lost product

- Mounts anywhere in plant without need for analyzer shelter

- Performance correlation to ASTM standards

In-Line And Field Deployable

- Verax VPA utilizes near-IR laser absorption spectroscopy and proprietary chemometric model library

- In-line at full pressure with no sample collection needed

- Multi-probe option for inlet/outlet or multiple stream measurement

- Custom probe design prevents fouling for maintenance-free use

- Wireless modem provide remote operation capability

Opportunities For Real-Time Analysis

- Problem: Customer was manually switching re-boiler to meet downstream spec. Traditional vapor pressure analyzer is ineffective due to high paraffin content, cycle time, and cost.

- Solution: After Verax VPA installation, operator is able to stabilize plant, confidently meet customer specifications, and increase average RVP by ~2 PSI.

- Result: 2-3% increase in overall plant financial returns. Two week payback time on analyzer.

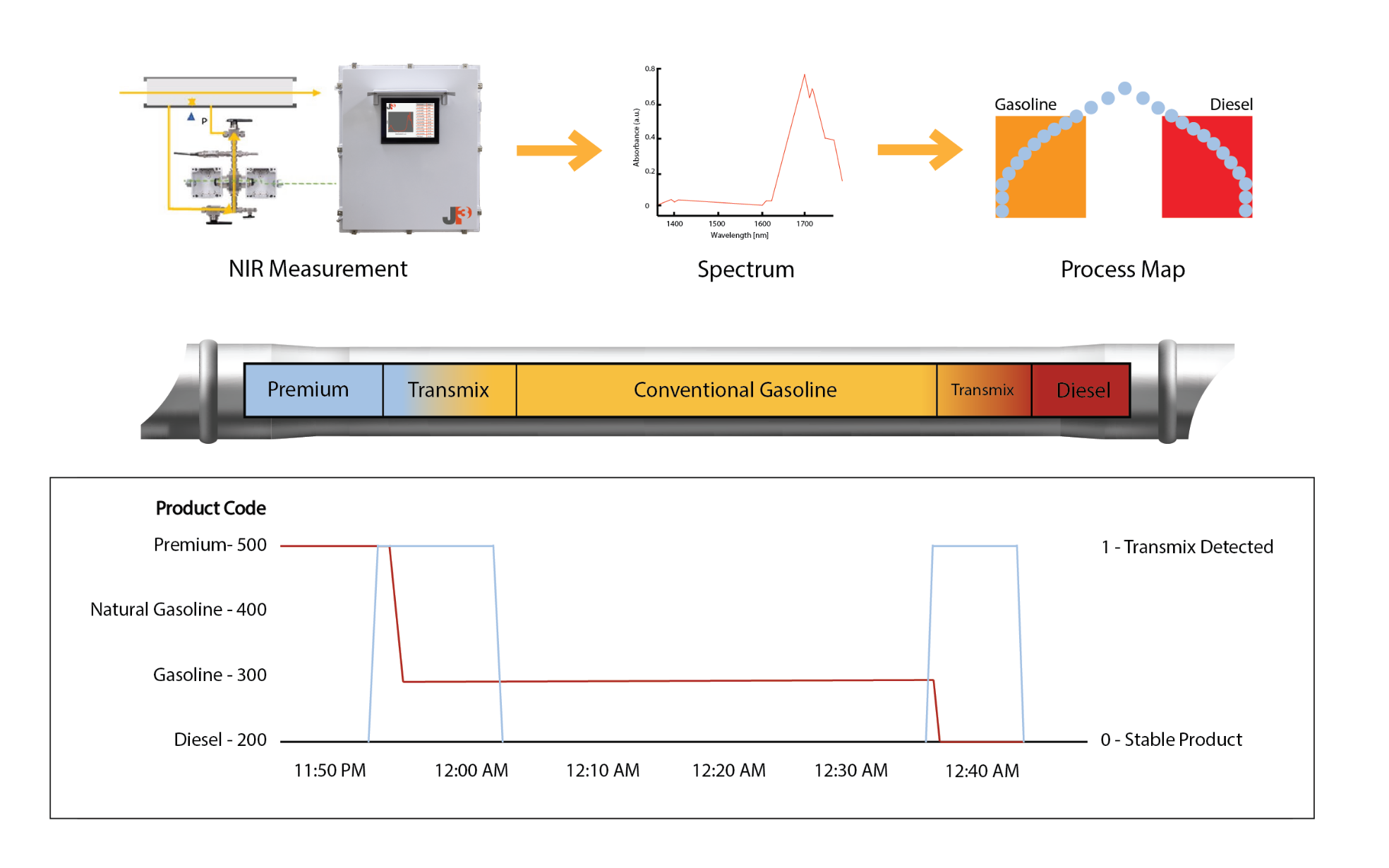

AIDA for Verax

Introducing AIDA, your groundbreaking solution in machine learning for optical signal analysis. This advanced system effortlessly identifies and analyzes product stability without needing constant calibrations, seamlessly integrating with all JP3 Verax spectrometers. Experience state-of-the-art precision in measuring hydrocarbon composition, Vapor Pressure, BTU, API gravity and more. With Verax’s robust design — no moving parts, consumables, or sample conditioning — enjoy lower maintenance and longer product life. Choose AIDA for reliable, efficient analysis.

Why Switch to This Powerful New Tool?

- Existing interface detection methods are either slow or unreliable.

- Manual sampling and analysis is slow and can take multiple hours to confirm that a new batch is on-spec.

- Existing on-line methods, such as acoustic densitometers, do not provide enough information to definitively identify interface boundaries.

- Reduces waste and improves profitability.

- Provides simple, actionable data.